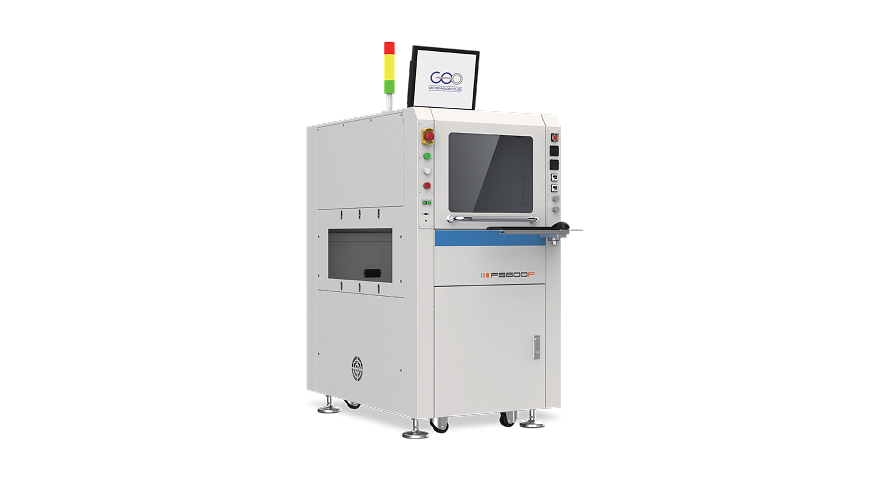

Full-automatic inline type dispensing/jetting machine

FS Series

Class-100 Dust-proof Model

FS 600 is available to High precision, high speed, high stability, Automatical cleaning of the residual glue, automatical weighing and correcting of gluing amount.

MES real-time docking, to real-time upload the production status information, and give alarm when system in abnormal condition

FS SERIES

Class-100 Dust-proof Model

FS 600 is available to High precision, high speed, high stability, Automatical cleaning of the residual glue, automatical weighing and correcting of gluing amount.

MES real-time docking, to real-time upload the production status information, and give alarm when system in abnormal condition

FS600A is a high-speed, high-precision, full-automatic dispensing system developed based on the latest dispensing process requirements for 3C components, final assembly, SMT areas. This equipment uses marble frame structure, linear-motor driving system, and piezoelectric jetting valve, etc. All configurations can meet the increasingly demanding dispensing process and system stability requirements.

Optional Configuration

· Piezoelectric jetting module

· Pneumatic jetting module

· Weighing module

· Rail heating module

· Jig absorption module

· Dual rail

· Automatic feeding & unloading module

Optional Configuration

· Piezoelectric jetting module

· Pneumatic jetting module

· Weighing module

· Rail heating module

· Jig absorption module

· Dual rail

· Automatic feeding & unloading module

Typical Applications

· FPC/PCB

· Semi-conductor 1st level packaging, underfill, overfill, edge bonding

· SMT 2nd level underfill, encap, overfill

· MEMS microphone air pressure meter

· CCM

· Fingerprint recognition

SPECIFICATIONS

| Model | FS-600 |

|---|---|

| Structure | Cabinet, Gantry, 3axis |

| Dimensions(mm) (W/O loading & unloading, FFU) |

770W × 1200D × 1450H |

| Outer cover | class-100 dust-free or painted color (Optional) |

| Input voltage | 2.5KW |

| Dispensing area(mm) (W/O loading & unloading) |

400W × 520D |

| Dispensing area(mm) (with loading & unloading) |

280W × 170D |

| Transmission type | X/Y:Linear motor Z:Servo + Screw |

| Repeat position accuracy(3sigma) | X/Y:±0.01mm Z:±0.005mm |

| Position accuracy(3sigma) | X/Y:±0.02mm Z:±0.01mm |

| Max. movement speed | X/Y:1300mm/s Z:500mm/s |

| Max. acceleration | X/Y:1.3g Z:0.5g |

| Conveyer speed | 300mm/s |

| Conveyor Height | 890~960mm |

| Conveyor width | 35~520mm (Front rail) |

| Conveyor belt load(kg) | 3kg |

| Max. Jig Thickenss | 0.5~9mm |

| Min. edge spacing | 4mm |

| Carrier Max width | 280mm |

| Carrier Max length | 180mm |

| Carrier Maximum height | 180mm |

| Carrier left-over quantity(max) | 3 boxes (With width of 180mm) |

HOME

HOME